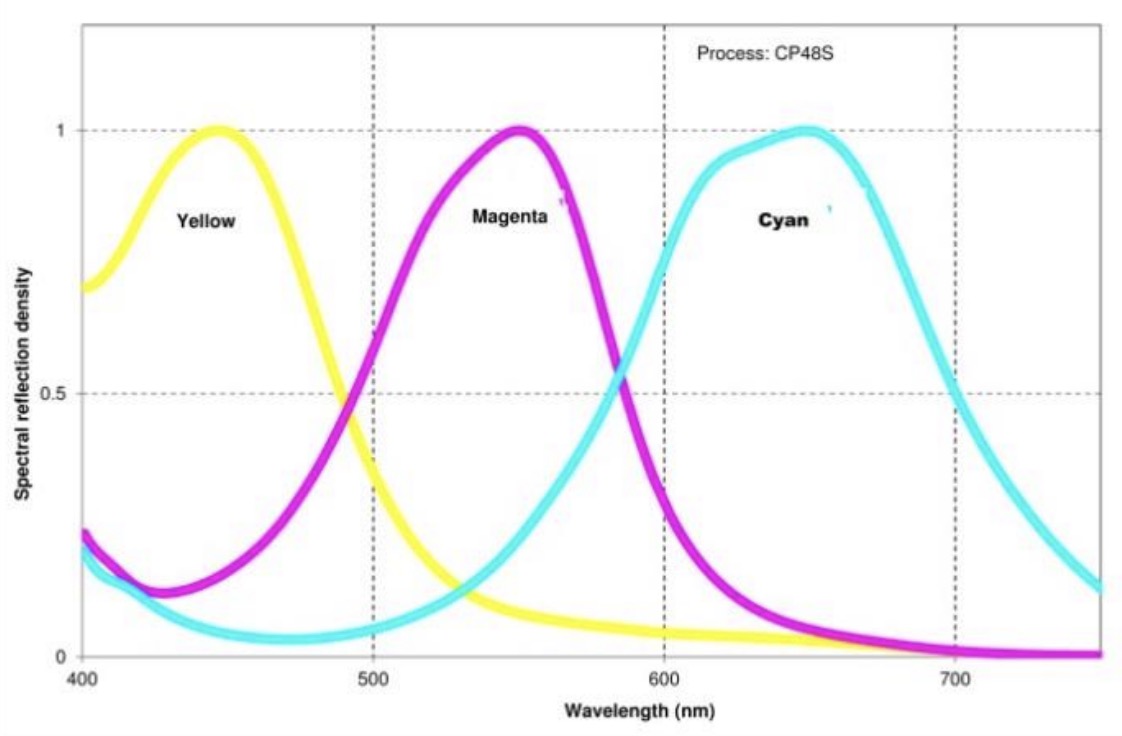

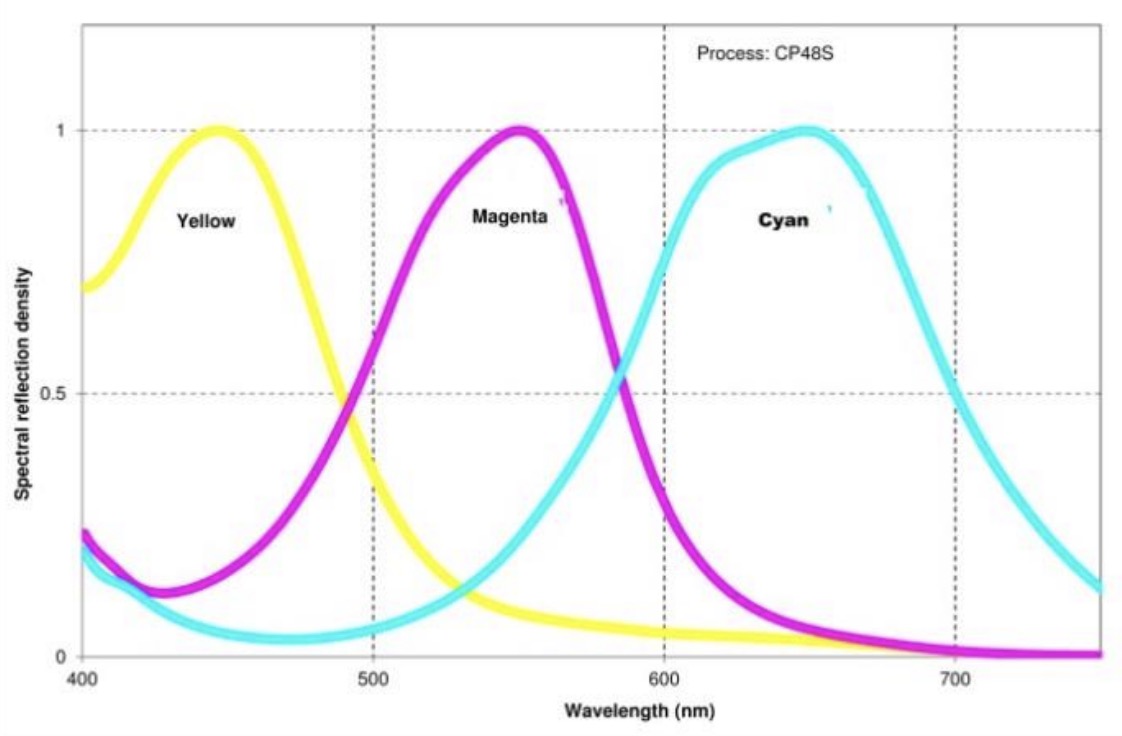

Color dyes spectrum of Fujifilm Fujicolor Crystal Archive

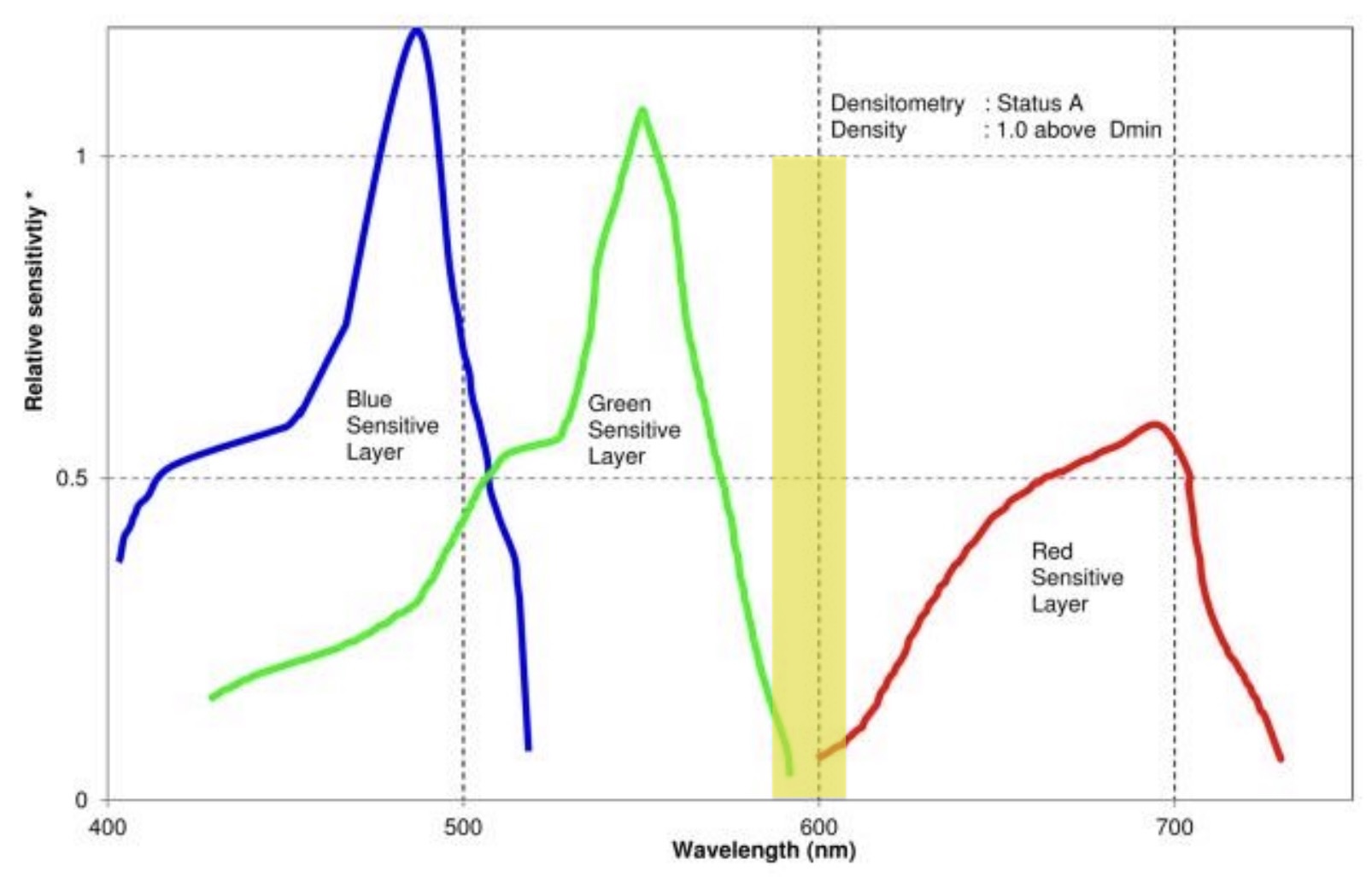

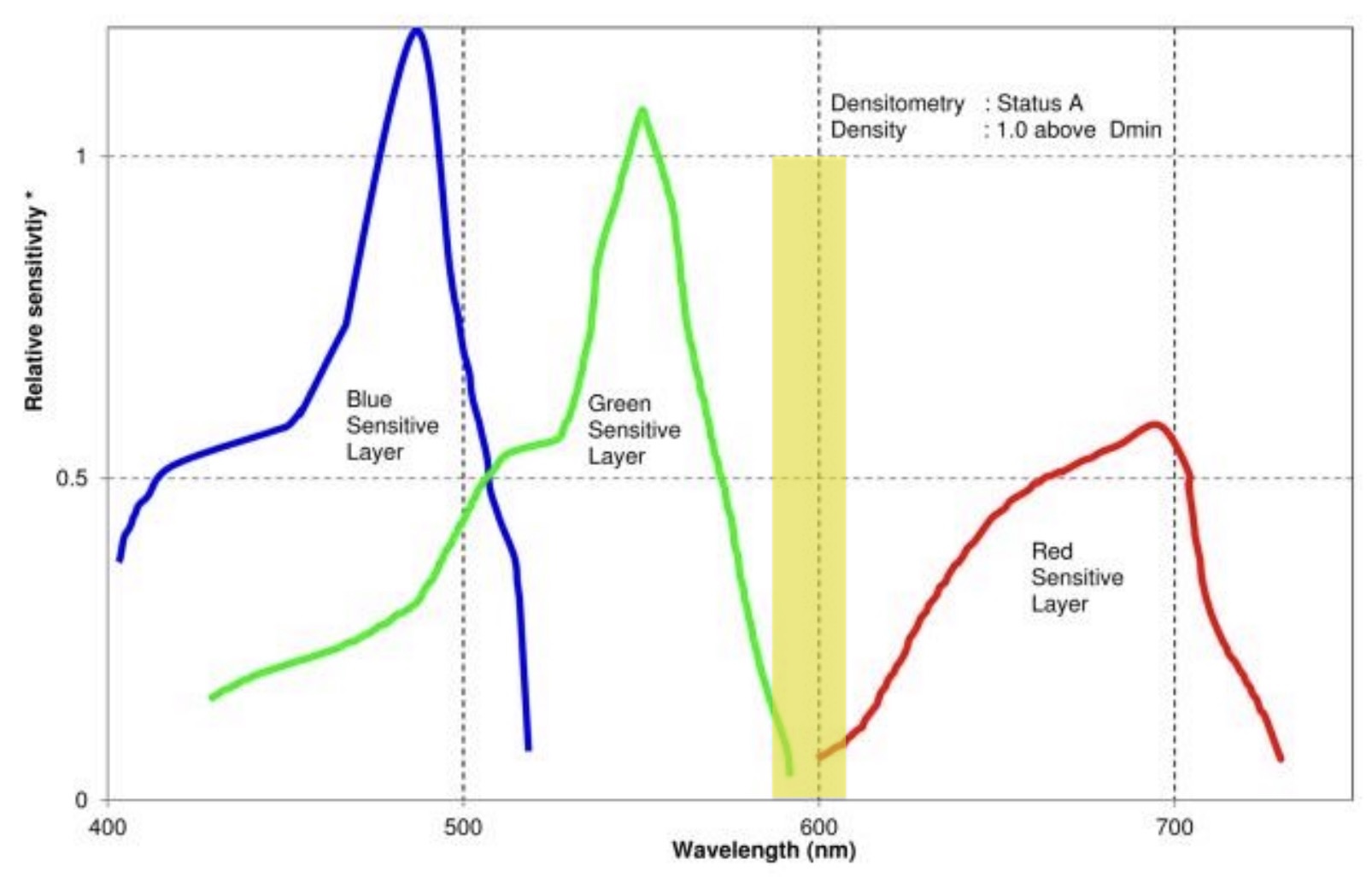

Color sensitivity spectrum of Fujifilm Fujicolor Crystal Archive

This article explores the role of safelights in RA-4 color darkrooms — why color papers are so sensitive, what strict conditions Kodak and Fuji set for safe illumination, and how traditional solutions like tungsten filters and sodium-vapor lamps were used. It explains the narrow spectral “safe window,” the limitations of older LED safelights, and introduces a modern approach: a compact, battery-powered LED flashlight with USB-C charging, dimming, and high-quality components, designed for small-batch production and now available for purchase through Ko-fi.

What Is a Safelight for a Color Darkroom? If you’ve ever printed in a black-and-white darkroom, you know how comforting a safelight can be. That soft amber glow makes the space feel alive and lets you work without stumbling in complete darkness. But the moment you step into a color darkroom, everything changes. RA-4 color printing uses paper that is far more sensitive than black-and-white. Suddenly, even the idea of a safelight becomes controversial.

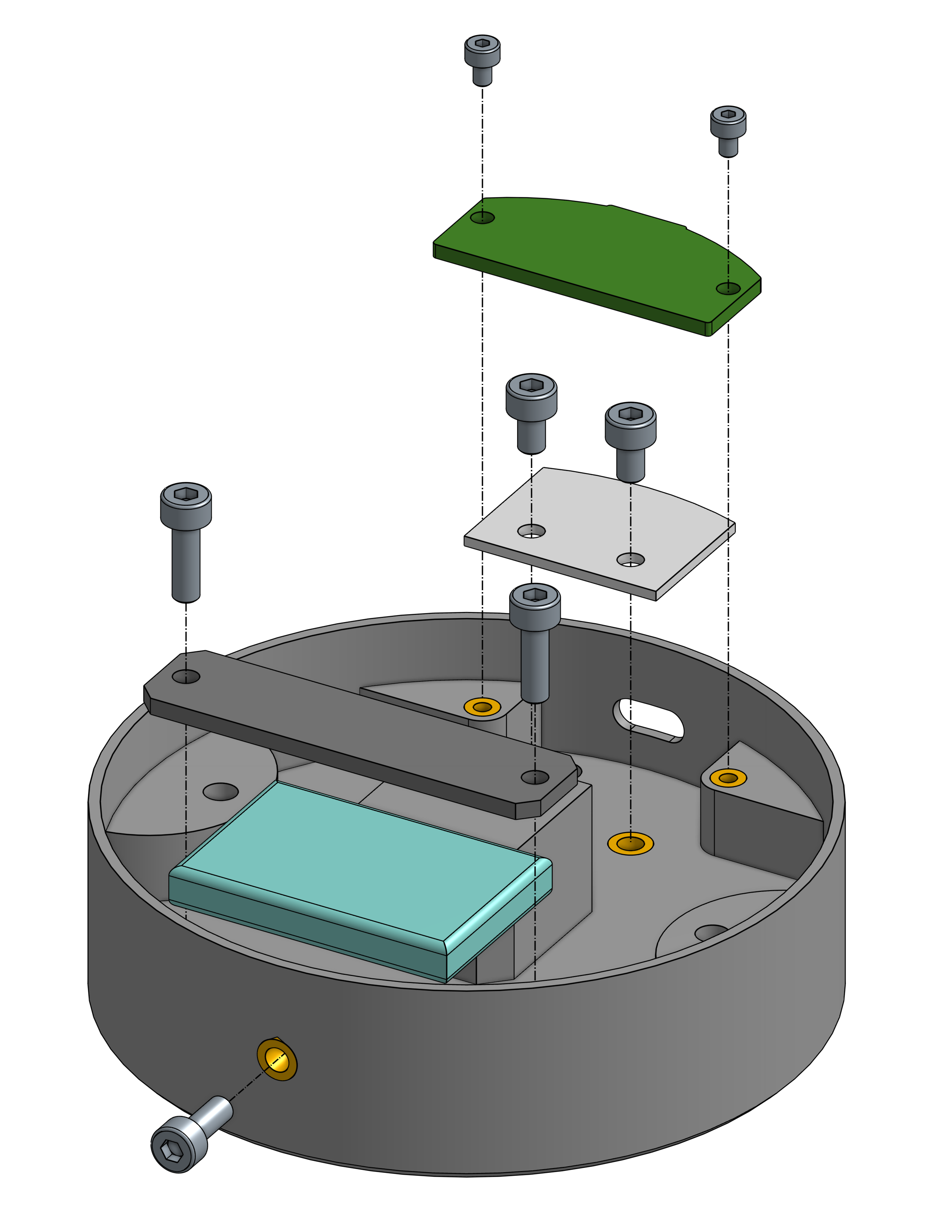

RA-4 paper isn’t a single emulsion. It’s built from three separate light-sensitive layers, each reacting to a different part of the spectrum and produce after processing colorful dyes.

Color dyes spectrum of Fujifilm Fujicolor Crystal Archive |

Color sensitivity spectrum of Fujifilm Fujicolor Crystal Archive |

When printing color with the RA-4 process, the usual advice is simple: work in total darkness. Color papers are highly sensitive, and even tiny amounts of stray light can shift colors or cause fogging. But the story doesn’t end there. Both Kodak and Fuji have published strict conditions under which a safelight can be used.

Fuji, for example, states:

These are very tight restrictions; far from the freedom black-and-white printers enjoy.

RA-4 color paper contains three emulsion layers, each sensitive to different regions of the visible spectrum (blue, green, and red). Between these peaks of sensitivity there is a narrow zone where the paper is least responsive to light. The orange-amber wavelength transmitted by filters such as Fuji 103A or Kodak Wratten 13 falls inside this zone of reduced sensitivity. Because the paper reacts very weakly there, a carefully controlled safelight can provide a minimal level of illumination without causing immediate fogging. This “safe window,” however, is extremely limited. If the light is too bright, too close, or left on for too long, even that wavelength will eventually expose the paper. That is why manufacturers restrict safelight use to low-wattage lamps, at least one meter away, and for no more than about one minute of exposure. In short: RA-4 paper isn’t completely blind to that orange light, but it is least sensitive to it. The safelight works only because it exploits this natural dip in sensitivity — giving printers a narrow margin of visibility in an otherwise dark working environment. In the same time modern paper produced only for mass printing with machines. Fast speed requires fast exposure values = paper became more sensitive and now it's harder to print by hands in the darkroom.

Safelights are not a new invention. Since the early days of darkroom printing, photographers have relied on specific light sources that emit very narrow parts of the spectrum. One of the most famous examples is the low-pressure sodium-vapor lamp. This type of lamp, used for decades in both scientific and photographic applications, produces an almost monochromatic yellow-orange light at about 589 nm. Because the emission line is so narrow, it falls mostly outside the peak sensitivity of black-and-white papers, making it highly suitable as a general darkroom light source.

|

Spectrum of a low-pressure sodium lamp. |

Fixed safelight in darkroom. |

For color printing the tolerances are stricter, but the principle is the same: by choosing a wavelength in the region where the paper is least sensitive, it is possible to work with a limited form of illumination. Modern safelight filters such as Fuji 103A or Kodak Wratten 13 apply the same idea, transmitting light in a narrow amber band that RA-4 paper is relatively less sensitive to.

Traditional safelight technology for color printing has always been a compromise. Tungsten lamps with filters or even sodium-vapor lamps could provide limited illumination, but they were bulky, inefficient, and difficult to control. On top of that, filters fade over time, wattage is hard to regulate precisely, and replacement parts are becoming increasingly rare. In the final years of mainstream color darkroom printing, early LED-based safelights did appear. But they were built with older LED technology that lacked spectral precision. Their emission bands were broader, less stable, and not always well matched to the safe window of RA-4 papers. This meant that their usability was limited and they never became a standard solution. That’s why I decided to revisit this problem with modern LED technology. Today’s LEDs can be engineered to emit in an extremely narrow band of the spectrum, exactly where RA-4 papers have the lowest sensitivity. Unlike old filters, they don’t fade, they generate less heat, and they can be paired with dimming electronics to fine-tune the brightness to safe working levels. My goal is to bring back a reliable, precise, and compact safelight solution for the color darkroom. By combining spectral accuracy with modern usability — USB power, stable output, long lifetime — it becomes possible to make RA-4 printing more comfortable again, without sacrificing the quality of the prints.

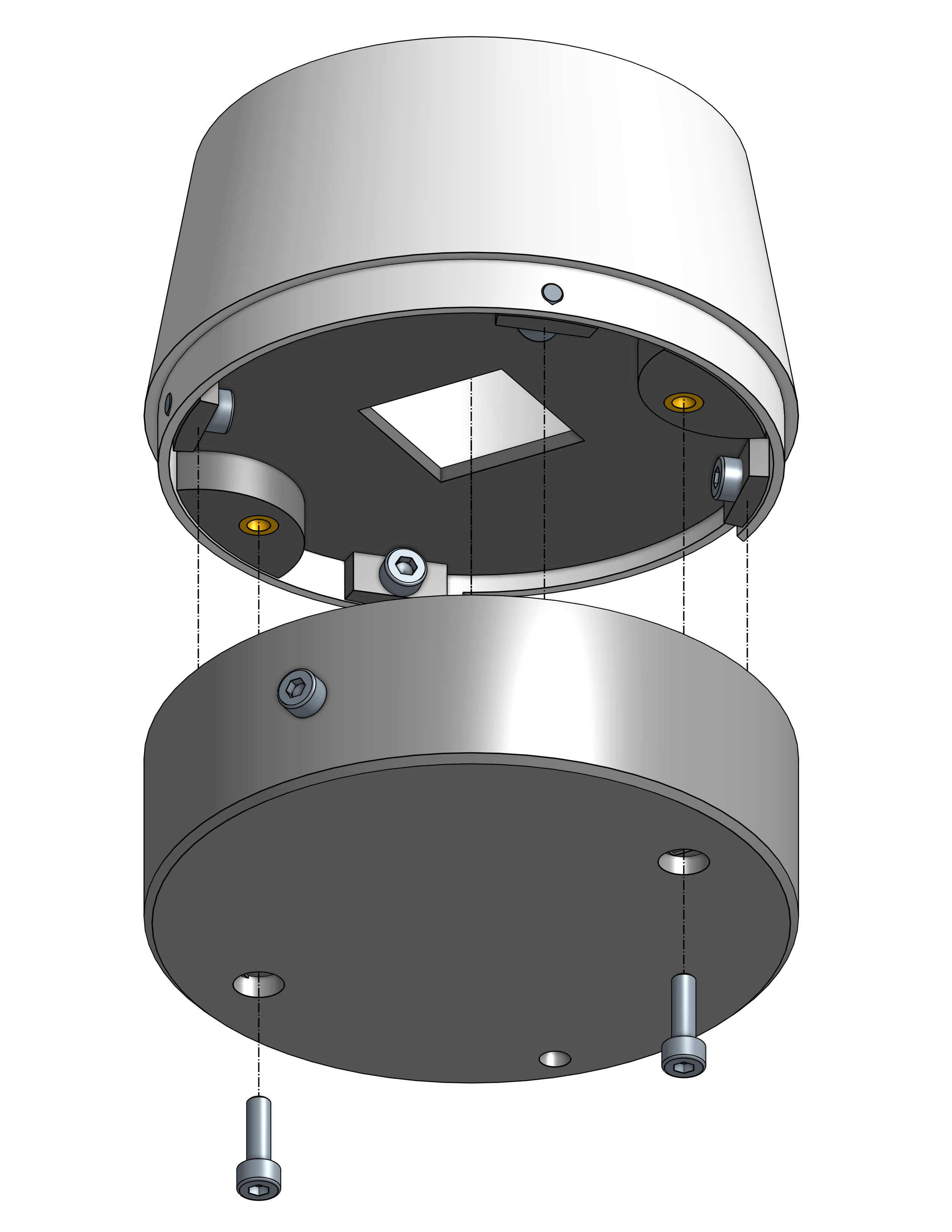

Instead of trying to recreate the old tungsten or early LED solutions, I chose to design something from scratch: a compact safelight flashlight built for today’s color darkrooms.

The key principles behind it are simple:

This approach brings together the spectral precision of modern LEDs with practical features that photographers expect today. The result is a safelight that feels contemporary, reliable, and sustainable — designed for those who still love working with real color prints.

|

|

|

|

From the beginning, my goal was to design a safelight that could be built without relying on large-scale manufacturing. The color darkroom market is small and highly specialized, which makes flexibility more valuable than mass production.

To achieve this, I focused on materials and components that are available everywhere:

This combination allows production in small batches, keeping the design practical, reproducible, and sustainable. At the same time, using only top-grade LEDs ensures the spectral precision required for RA-4 printing.

|

A safelight is only as safe as it tests in your darkroom. Room size, wall color, lamp height, and even paper batch all matter. The protocol below gives you a repeatable way to verify limits.

Your safe time is the longest step with no fog. Apply a safety margin of 50–70%.

Example: If fog begins at 4 min, keep paper under safelight ≤ 2–3 min.

Keep notes for reproducibility:

Need a fast answer? Do 8 steps at 30s each (total 4 min). If the 4-min step is clean, you likely have margin—but still run the full test later.

After months of design, testing, and refinement, I’m making this safelight flashlight available to the community. Built for small darkrooms and tuned for RA-4 safety, it features battery power, USB-C passthrough charging, touch dimming, and modern narrow-band LEDs for spectral precision.

Each unit is assembled in small batches and shipped on demand.